Xinghua Jiahe Foods Co., Ltd is China Dehydrated Tomato Manufacturers and Dehydrated Tomato Factory, located in Xinghua city Jiangsu province, established in 2003. We are an experienced manufacturer and distributor of air dried vegetables and fruits in China. After more than 10 years fast development, now we are proud of being one of the top 3 manufacturers in China. We have built ourselves as a whole-range of consistent, affordable, and safe food products to the ingredient market. Our plant takes up an area of 25`000㎡with an annual capacity 8000 tons. We also have more than 300 hand-sorting workers, this is the last critical control point. Some defect materials which are out control of the facilities will be removed clearly. We have a multiple supply range. As Dehydrated Tomato Exporter & Importer, we can supply you not only flake, dice, granules -- but also powder according to your need. All finish products are made from selected, fresh materials.

Dehydrated Tomato

Field fresh tomatoes which are washed, cored, trimmed, diced and dried. The processing sequence initiates with rigorous cleaning protocols, material segregation, and HACCP compliance measures before proceeding to particle size modification via blade cutting or abrasive milling techniques

- 3/8",

- 1/4"

- 1/8"

- CUSTOM SIZE

Dried tomato flakes are used for convenience foods (instant soup mixes, cup noodle vegetable toppings), seasoning systems (tomato powder blends, sauce premixes), baked goods (pizza toppings, focaccia garnishes), health-focused products (freeze-dried snack crisps, meal replacements), and pet food (wet food flavor enhancers).

Authentic reliable quality naturally stands out and fears no comparison.

Provide you with the latest enterprise and industry news.

-

How resistant is the Dehydrated Green Pepper to microbial growth, mold, or spoilage during storage and transport?

Low Moisture Content: One of the most critical factors contributing to the microbial stability of Dehydrated Green Pepper is its extremely low moisture content achieved during the dehydration process. Water is a fundamental requirement for the growth of bacteria, yeast, and mol...

-

How should Dehydrated Tomato be stored to maintain its shelf life, color, and flavor over time?

Temperature Control Maintaining the proper storage temperature is critical for preserving the quality of Dehydrated Tomato over time. Ideally, it should be stored in a cool, dry environment between 10–25°C (50–77°F). Elevated temperatures accelerate chemical reactions such as Mai...

-

How does the particle size, cut type (shredded, sliced, diced), or granulation of Dehydrated Cabbage affect rehydration performance and application in food processing?

Particle Size and Surface Area:The particle size of Dehydrated Cabbage has a profound effect on its water absorption rate, rehydration kinetics, and suitability for different culinary applications. Smaller particles or finely shredded cabbage present a higher surface-area-to-vo...

Product Overview and Production Process Introduction

Dehydrated tomato is made from fresh and ripe tomatoes in the field. They are processed by washing, stalk removal, dicing, air drying and other processes to make them a kind of dried vegetable product that can be stored at room temperature. The dehydration process not only significantly extends the shelf life of tomatoes, but also achieves efficient volume compression and transportation convenience while maintaining their natural color, flavor and most nutrients.

Tomatoes themselves are a fruit and vegetable crop with strong flavor and rich nutrition. They are rich in lycopene, vitamin C, dietary fiber and various minerals. In traditional processing, tomatoes are mostly used to make jams, ketchup or frozen products, while the rise of dehydrated tomatoes provides the food industry with a more flexible, convenient and cost-effective option. Its product forms include thin slices, dices, granules and powders, and are widely used in fast food, condiments, baked products, functional snacks and pet food. They can be used alone or mixed with other ingredients.

As an important manufacturer in the field of air-dried vegetables in China, Xinghua Jiahe Food Co., Ltd. relies on its advanced dehydration technology and stable raw material supply system to provide the market with high-quality dehydrated tomato products. Since its establishment in 2003, the company has continued to cultivate the field of dried fruits and vegetables, and has now grown into one of the leading suppliers of dehydrated vegetables and fruits in China.

The quality of dehydrated tomatoes depends largely on the selection of raw materials and the control of production processes. Jiahe Food uses fresh tomatoes directly from the place of origin to ensure that the raw materials are uniformly mature, the flesh is full, and there is no pesticide residue pollution. Before entering the production link, tomatoes must undergo strict sorting and cleaning processes to remove mud, lesions and foreign matter, and meet the various standards of the HACCP food safety control system.

In the dehydration processing stage, Jiahe uses low-temperature rapid hot air drying technology to scientifically control temperature and time to avoid the destruction of active ingredients such as lycopene and vitamin C at high temperatures. In order to ensure the consistency of product appearance and moisture content, each batch of products needs to be adjusted in particle size and manually selected after drying. The company is equipped with more than 300 manual quality inspectors to conduct the final screening of the finished products, remove debris, irregular shapes or color deviations, and ensure product stability and controllability.

Jiahe Food has an annual production capacity of up to 8,000 tons. The production plant covers an area of 25,000 square meters and has built several modern dehydration production lines to support the supply of tomato products of various specifications, including tomato slices, dices, coarse grains, fine powder and other forms to adapt to the formulation and process requirements of different customers around the world. In addition, the company also has the ability to customize and can adjust the product particle size, drying degree and packaging form according to customer needs to meet diversified market applications.

Nutritional value and health advantages and their application scope

Tomatoes are known as "rubies among vegetables" because of their unique nutritional structure, and dehydrated tomatoe present this nutritional advantage in a higher density form, becoming an important raw material for the development of contemporary health foods. Its core nutritional advantages are reflected in the following aspects:

Rich in lycopene: lycopene is a natural carotenoid with strong antioxidant capacity. It can effectively neutralize free radicals, prevent cardiovascular diseases, reduce the risk of certain cancers, and especially protect prostate health. The dehydration process retains a higher content of lycopene, which is particularly suitable for the development of health foods or nutritional supplements.

Vitamin C and dietary fiber: Vitamin C is an important component for promoting immunity, anti-oxidation and enhancing collagen synthesis, while dietary fiber helps intestinal health, promotes detoxification and regulates blood sugar. Scientifically dehydrated tomatoes retain their original vitamin C and dietary fiber structure, making them an ideal ingredient for functional snacks and meal replacement products.

Natural low-fat and low-calorie: Dehydrated tomatoes do not introduce any fat components while removing water, and they have low calories themselves, making them suitable for the development of nutritious foods suitable for people who want to lose weight, control sugar, and control fat.

Green coloring and natural seasoning: The natural bright red color of tomatoes comes from their pigment molecules, without the need to add artificial synthetic pigments. Use in seasonings, baked products or ready-to-eat products to enhance visual appeal and natural flavor perception.

Dehydrated tomatoes have a wide range of application prospects in the food industry due to their unique flavor, diverse forms, and strong adaptability. According to the export formula statistics of Jiahe Food, its main applications can be summarized into the following categories:

Fast food and prepared food: In pre-prepared dishes such as instant noodles, instant porridge, cup soup, frozen pasta, etc., tomato particles or slices are widely used as the main ingredients to enhance the sweet and sour flavor and color.

Premix of condiments and sauces: Tomato powder or tomato granules are often used in tomato sauce powder, pizza sauce base, spicy seasoning, Mexican flavor, providing natural acidity and fruity aroma for the products.

Functional snacks: Such as tomato crisps, tomato energy bars, tomato nut mixed snacks, etc., are deeply loved by consumers who pursue natural, low-sugar, non-fried snacks.

Baking and catering ingredients: In the baking field, dehydrated tomato slices can be used as natural decoration and flavor embellishment for products such as pizza, focaccia, and savory bread; in catering kitchens, they can be directly rehydrated and used to quickly cook various pastas, stews, marinades, etc.

Pet food: As a natural nutritional ingredient, dehydrated tomatoes are also added to pet wet food to enhance the flavor while supplementing vitamins and antioxidants.

Company advantages guarantee stable supply

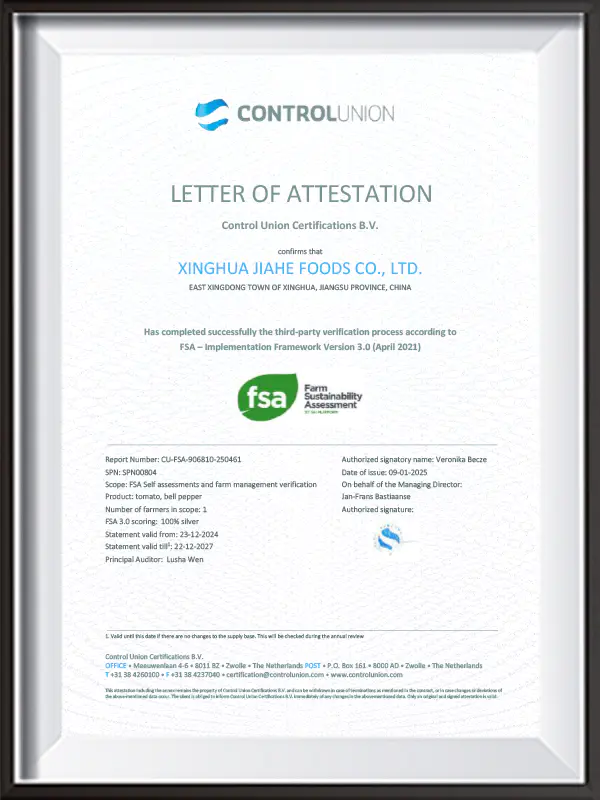

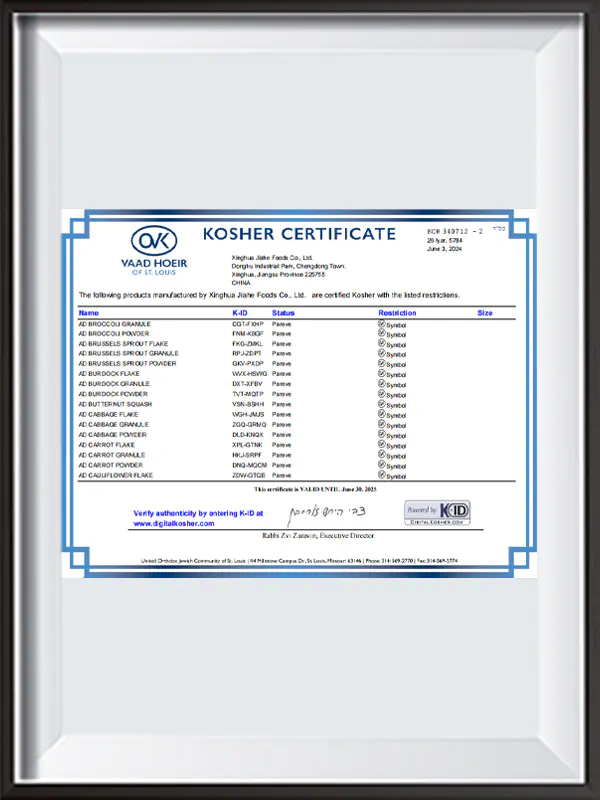

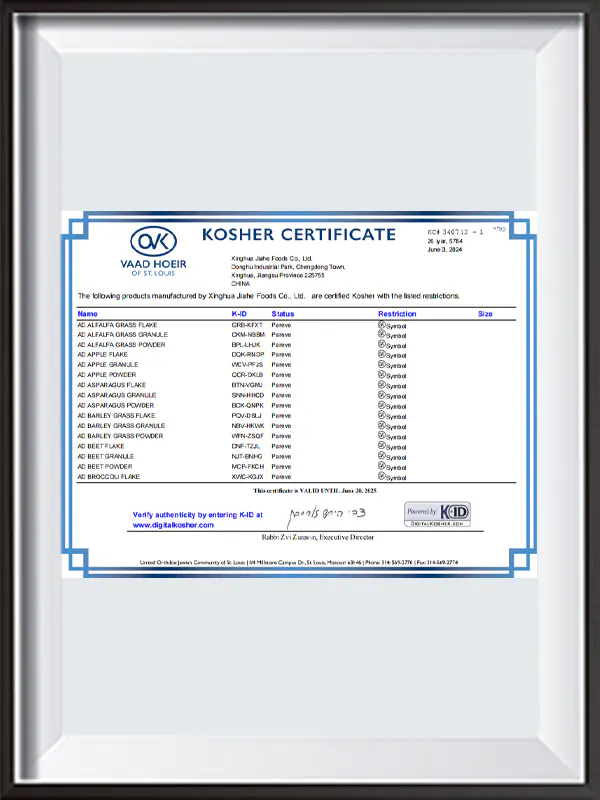

Xinghua Jiahe Foods Co., Ltd. has built a stable raw material base, strict quality control system and efficient international trade network based on its many years of experience in dehydrated vegetables. The company has not only passed a number of international certifications such as HACCP and ISO, but also continuously introduced modern automation equipment to improve production efficiency and product consistency. More than 300 front-line manual sorting workers constitute the last line of quality defense to ensure that each batch of products meets the high standards of the export market.

In addition, Jiahe Food pays attention to the construction of a product traceability system. From the storage of raw materials to the shipment of products, every link is strictly recorded to ensure the full chain closed loop of food safety and quality responsibility. The company currently serves customers in many countries and regions around the world, providing stable raw material support for many seasoning brands, ready-to-eat product factories, chain supermarkets and catering companies.

English

English Français

Français Español

Español