Xinghua Jiahe Foods Co., Ltd is China Dehydrated Sweet Potato Manufacturers and Dehydrated Sweet Potato Factory, located in Xinghua city Jiangsu province, established in 2003. We are an experienced manufacturer and distributor of air dried vegetables and fruits in China. After more than 10 years fast development, now we are proud of being one of the top 3 manufacturers in China. We have built ourselves as a whole-range of consistent, affordable, and safe food products to the ingredient market. Our plant takes up an area of 25`000㎡with an annual capacity 8000 tons. We also have more than 300 hand-sorting workers, this is the last critical control point. Some defect materials which are out control of the facilities will be removed clearly. We have a multiple supply range. As Dehydrated Sweet Potato Exporter & Importer, we can supply you not only flake, dice, granules -- but also powder according to your need. All finish products are made from selected, fresh materials.

Dehydrated Sweet Potato

Fresh sweet potatoes which are washed, blanched, trimmed, diced and dried.The processing sequence initiates with rigorous cleaning protocols, material segregation, and HACCP compliance measures before proceeding to particle size modification via blade cutting or abrasive milling techniques

- 3/8"

- POWDER

- CUSTOM SIZE

Dried sweet potatoes are used in a wide variety of applications including seasoning blends, sauces, soups and stews, pasta products, chips and snacks, meats and sausages, ready meals, and pet food products.

Authentic reliable quality naturally stands out and fears no comparison.

Provide you with the latest enterprise and industry news.

-

How resistant is the Dehydrated Green Pepper to microbial growth, mold, or spoilage during storage and transport?

Low Moisture Content: One of the most critical factors contributing to the microbial stability of Dehydrated Green Pepper is its extremely low moisture content achieved during the dehydration process. Water is a fundamental requirement for the growth of bacteria, yeast, and mol...

-

How should Dehydrated Tomato be stored to maintain its shelf life, color, and flavor over time?

Temperature Control Maintaining the proper storage temperature is critical for preserving the quality of Dehydrated Tomato over time. Ideally, it should be stored in a cool, dry environment between 10–25°C (50–77°F). Elevated temperatures accelerate chemical reactions such as Mai...

-

How does the particle size, cut type (shredded, sliced, diced), or granulation of Dehydrated Cabbage affect rehydration performance and application in food processing?

Particle Size and Surface Area:The particle size of Dehydrated Cabbage has a profound effect on its water absorption rate, rehydration kinetics, and suitability for different culinary applications. Smaller particles or finely shredded cabbage present a higher surface-area-to-vo...

What is dehydrated sweet potato?

Dehydrated sweet potato is a sweet potato product that has been processed by a specific process, usually used to extend the shelf life and facilitate storage and transportation. The processing of dehydrated sweet potatoes starts with the picking of fresh sweet potatoes, and then goes through steps such as washing, blanching, trimming, cutting and drying, and finally presents a dry product that is easy to store and transport for a long time. Dehydrated sweet potatoes not only maintain the nutritional value of sweet potatoes, but also have a variety of processing uses. They are widely used in the food industry, catering industry and home cooking.

Processing process: The production of dehydrated sweet potatoes starts with a strict cleaning process to ensure that the dirt and impurities on the surface of the sweet potatoes are removed. Subsequently, blanching can effectively sterilize and remove some enzymes to prevent the sweet potatoes from changing color or producing a bad taste during the dehydration process. During the trimming process, unqualified or defective sweet potatoes are removed to ensure the quality consistency of the final product. The cutting stage uses knife cutting or abrasive grinding to convert the sweet potatoes into uniform particles or flakes. Finally, the drying process uses hot air drying or freeze-drying technology to minimize moisture and extend the shelf life of the product.

Advantages of dehydrated sweet potatoes: One of the advantages of dehydrated sweet potatoes is that they extend the shelf life of sweet potatoes. Fresh sweet potatoes are easy to rot at room temperature, while the dehydrated products not only greatly increase the shelf life, but also facilitate transportation and storage. Dehydrated sweet potatoes retain most of the nutrients, such as dietary fiber, vitamin C, vitamin A, etc., and are a very healthy food choice.

Why choose dehydrated sweet potatoes instead of fresh sweet potatoes?

Choosing dehydrated sweet potatoes instead of fresh sweet potatoes is mainly based on the following reasons:

Extended shelf life and easy transportation: Fresh sweet potatoes have a short shelf life and will rot or sprout in just a few days or a week or two. On the contrary, after the dehydrated sweet potatoes are dehydrated, the water is removed and the growth of microorganisms is also inhibited, which greatly extends their shelf life. Dehydrated sweet potatoes can not only be stored at room temperature, but also greatly reduce the risk of deterioration during transportation, which is particularly suitable for long-distance international trade.

Nutrients are not easy to lose: Through modern dehydration technology, the water in sweet potatoes is removed, but most nutrients, such as fiber, vitamins, minerals, etc. can maintain a high stability. This makes dehydrated sweet potatoes an efficient source of nutritional supplements, especially suitable for use in the food industry, such as ready-to-eat foods, instant noodles, sauces, etc.

Economic benefits: Dehydrated sweet potatoes have higher economic value. Since fresh sweet potatoes are easily wasted during processing and transportation, the weight and volume of dehydrated sweet potatoes can be significantly reduced after the water is removed, which is convenient for long-term storage and bulk sales. In addition, the long-term preservation of dehydrated products also reduces the supply instability caused by seasonal changes, which helps to balance market supply and stabilize prices.

Efficient processing and application: Dehydrated sweet potatoes use modern technologies such as knife cutting and abrasive grinding during processing, which can more accurately control the particle size of the product to meet the needs of different customers. Its wide range of application scenarios also makes it one of the indispensable raw materials in the food industry. From the catering industry to home kitchens, the convenience and versatility of dehydrated sweet potatoes make it an important part of the global food industry.

How to ensure the quality and safety of dehydrated sweet potatoes?

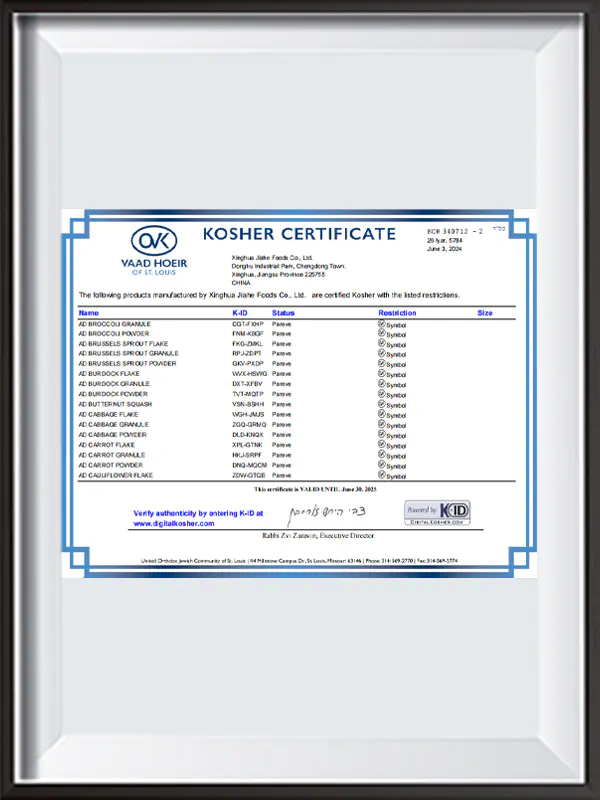

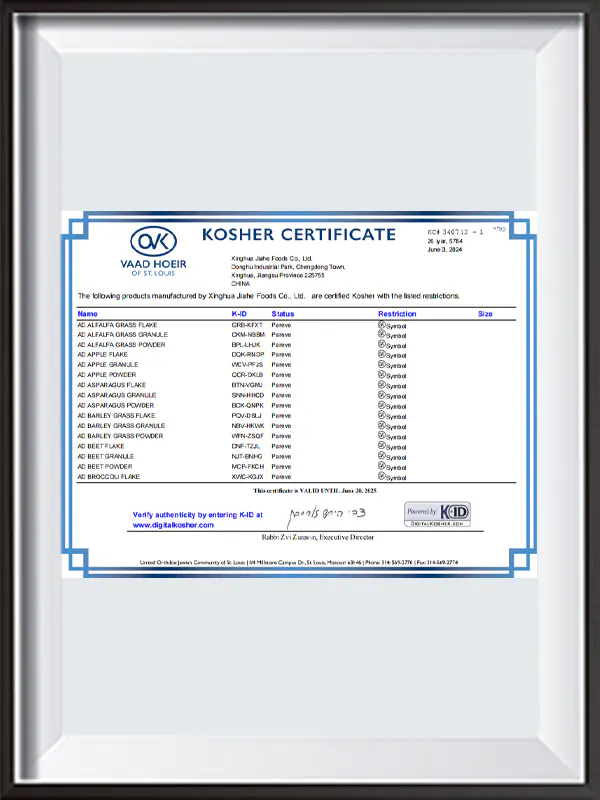

Quality control of dehydrated sweet potatoes is a multi-step, strictly controlled process, covering every link from raw material procurement to processing, storage and transportation. In order to ensure that the product quality of dehydrated sweet potatoes meets food safety standards, the company has taken a number of measures to strictly control quality during the production process.

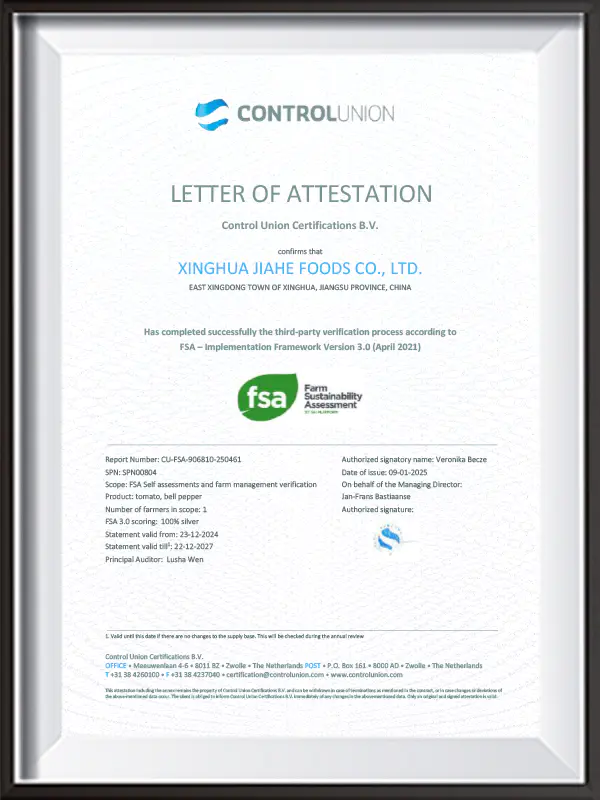

Farm management and planting environment monitoring: Xinghua Jiahe Foods Co., Ltd strictly controls the use of pesticides in the planting management of sweet potatoes, and keeps detailed records of each pesticide use to ensure traceability. At the same time, preliminary pesticide residues and heavy metal tests are carried out on soil and water sources. Only when the planting environment is safe can sweet potatoes be planted, and the quality and safety of agricultural products can be controlled from the source.

Independent third-party testing: Once the sweet potatoes are harvested, the company immediately sends the fresh raw materials to an independent third-party testing agency for comprehensive pesticide residue and heavy metal testing. This link is a key step to ensure the quality of dehydrated sweet potatoes. Through strict third-party testing, it is ensured that there are no quality risks before the product enters the processing process.

Quality control during processing: During the processing of dehydrated sweet potatoes, the company follows the HACCP standards and takes strict quality control measures. From washing and blanching to cutting and drying, each production link is strictly controlled. Through high-standard production facilities and precise processing technology, external contamination and product quality fluctuations are minimized.

Food safety and traceability system: The company is committed to establishing a complete food safety management system to record and trace every link in the production process in detail. Once a quality problem occurs, it can be quickly traced back to the raw materials and production details of a specific batch to ensure that measures are taken in the shortest time to maximize the food safety of consumers.

Strict storage and transportation management: Dehydrated sweet potatoes also need special attention during storage and transportation. The company uses modern storage facilities and strictly controls temperature and humidity to ensure the stability of product quality throughout the transportation chain. In addition, quality inspections will be carried out before the products are shipped to ensure that each batch of products meets the factory standards before they can be shipped.

English

English Français

Français Español

Español