Xinghua Jiahe Foods Co., Ltd is China Dehydrated Purple Sweet Potato Manufacturers and Dehydrated Purple Sweet Potato Factory, located in Xinghua city Jiangsu province, established in 2003. We are an experienced manufacturer and distributor of air dried vegetables and fruits in China. After more than 10 years fast development, now we are proud of being one of the top 3 manufacturers in China. We have built ourselves as a whole-range of consistent, affordable, and safe food products to the ingredient market. Our plant takes up an area of 25`000㎡with an annual capacity 8000 tons. We also have more than 300 hand-sorting workers, this is the last critical control point. Some defect materials which are out control of the facilities will be removed clearly. We have a multiple supply range. As Dehydrated Purple Sweet Potato Exporter & Importer, we can supply you not only flake, dice, granules -- but also powder according to your need. All finish products are made from selected, fresh materials.

Dehydrated Purple Sweet Potato

Fresh purple sweet potatoes which are washed, pelled, trimmed, diced and dried. The processing sequence initiates with rigorous cleaning protocols, material segregation, and HACCP compliance measures before proceeding to particle size modification via blade cutting or abrasive milling techniques

- 3/8"

- POWDER

- CUSTOM SIZE

Dried purple sweet potatoes are used in a wide variety of applications including seasoning blends, sauces, soups and stews, pasta products, chips and snacks, meats and sausages, ready meals, and pet food products.

Authentic reliable quality naturally stands out and fears no comparison.

Provide you with the latest enterprise and industry news.

-

How resistant is the Dehydrated Green Pepper to microbial growth, mold, or spoilage during storage and transport?

Low Moisture Content: One of the most critical factors contributing to the microbial stability of Dehydrated Green Pepper is its extremely low moisture content achieved during the dehydration process. Water is a fundamental requirement for the growth of bacteria, yeast, and mol...

-

How should Dehydrated Tomato be stored to maintain its shelf life, color, and flavor over time?

Temperature Control Maintaining the proper storage temperature is critical for preserving the quality of Dehydrated Tomato over time. Ideally, it should be stored in a cool, dry environment between 10–25°C (50–77°F). Elevated temperatures accelerate chemical reactions such as Mai...

-

How does the particle size, cut type (shredded, sliced, diced), or granulation of Dehydrated Cabbage affect rehydration performance and application in food processing?

Particle Size and Surface Area:The particle size of Dehydrated Cabbage has a profound effect on its water absorption rate, rehydration kinetics, and suitability for different culinary applications. Smaller particles or finely shredded cabbage present a higher surface-area-to-vo...

Introduction to dehydrated purple sweet potato products and processing procedures

Dehydrated purple sweet potato is made from fresh purple sweet potato, which is processed through strict selection, cleaning, peeling, trimming, cutting (or dicing), low-temperature drying and other processes. It is a food raw material product with a long shelf life and convenient storage and transportation. This product retains the main nutrients and natural color of purple sweet potato, and is suitable for wide use in many fields such as condiments, convenience foods, healthy snacks, and pet food.

Common forms of dehydrated purple sweet potato include: flakes, granules, dices and powders, which can be customized according to customer needs. Different particle sizes and forms make it more adaptable and flexible in the food industry, and improve its compatibility in different processing formulas.

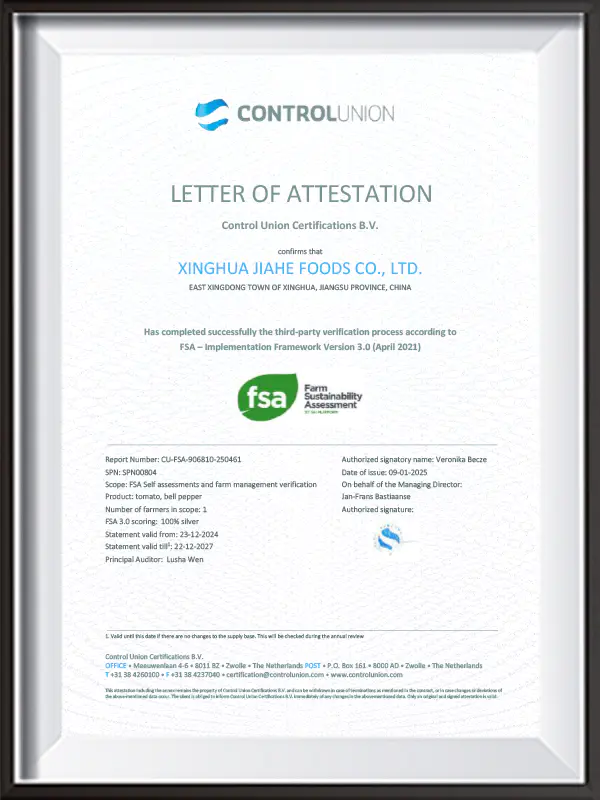

The quality of dehydrated purple sweet potato depends largely on the processing technology and quality control system behind it. The production process of Xinghua Jiahe Foods Co., Ltd, Jiangsu Province strictly implements the HACCP food safety management system, and sets critical control points at every link to ensure product safety, stability and traceability.

Raw material selection: Use high-quality fresh purple sweet potatoes of the season, strictly grade them, and remove unqualified tubers such as those with diseases and rot;

Washing and peeling: Use multi-stage water washing and physical peeling equipment to effectively remove mud and skin to ensure cleanliness;

Trimming and cutting: Trim and cut into granules, dices or slices according to the shape of the finished product, and use a combination of knife cutting and grinding to ensure neat cut surfaces and consistent particle sizes;

Dehydration and drying: Use hot air drying or low-temperature air drying technology to remove more than 80% of moisture while retaining color and flavor;

Manual sorting: The factory has more than 300 hand-selected workers who conduct final inspections on dried products to remove foreign objects or defective products that cannot be identified by the equipment to ensure high consistency and safety;

Crushing and grading (optional): If customers have needs, dehydrated purple sweet potatoes can be further ground into powder to meet specific ingredients or premix uses.

Through refined process management and the investment in automated equipment, Jiahe Food not only ensures large-scale supply capabilities, but also achieves high consistency in product quality and hygienic and safety control.

Nutritional ingredients and functional advantages

Purple sweet potatoes are widely regarded as "antioxidant star raw materials" because they are rich in natural anthocyanins, dietary fiber, multiple vitamins and minerals. After scientific dehydration processing, the main nutrients in purple sweet potatoes are retained.

1. Rich in anthocyanins: Anthocyanins are the most representative natural pigments and functional ingredients in purple sweet potatoes. They belong to polyphenol compounds and have strong antioxidant activity. They can remove free radicals, reduce cell oxidative damage, delay the aging process, and to a certain extent prevent chronic diseases such as cardiovascular and cerebrovascular diseases, diabetes, and certain types of cancer. Compared with other purple fruits and vegetables, purple sweet potatoes have a higher content of anthocyanins and good stability, which can be better retained in a reasonably controlled dehydration process. Therefore, dehydrated purple sweet potatoes can not only be used as functional ingredients, but also as a natural antioxidant source added to nutritional meal replacements, dietary supplement powders, health drinks and other products to meet the modern people's needs for "integrated diet therapy".

2. Low fat and low calories: Purple sweet potatoes have an extremely low total fat content, and their calories are much lower than those of staple foods such as rice and flour, and other starchy processed foods. Therefore, they are widely considered to be ideal "alternative carbohydrate" raw materials. For people with special needs such as weight control, blood lipids, and diabetic diet management, purple sweet potato products (including dehydrated purple sweet potato powder) can be used as the basic raw materials for healthy staple foods, nutritious meal replacements, or energy bars. After drying, the volume of dehydrated purple sweet potatoes is reduced and the nutrients are concentrated, which makes it easier to achieve the functional goal of high nutritional density in a small ratio, which not only increases the added value of the product, but also makes the product more acceptable to the market.

3. Rich in dietary fiber: Purple sweet potatoes are rich in soluble and insoluble dietary fiber, especially pectin and cellulose. After entering the intestine, these fibers can promote intestinal peristalsis, enhance satiety, reduce fat absorption, and help regulate the balance of intestinal flora, improve constipation and indigestion. Through the dehydrated purple sweet potato granules, powder or minced form, these fiber components are still retained in the raw materials, making it one of the ideal raw materials for improving intestinal function foods (such as meal replacement powder, healthy cereal, probiotic granules, etc.), with the practical value of "food-grade nutritional supplements".

4. Natural purple pigment source: At a time when food color matching is increasingly transforming towards "naturalization", purple sweet potatoes provide a natural purple-red pigment source that does not require additives. Especially in scenarios where it is not appropriate to use artificial synthetic pigments or to meet the requirements of natural ingredients in the European Union, North America and other places, dehydrated purple sweet potatoes have become an important "pigment and nutrition" dual-functional raw material.

Wide range of industrial application scenarios

Dehydrated purple sweet potato has become a versatile raw material choice in multiple industries due to its adaptability to products with various particle sizes and forms:

1. Seasoning and compound powder field: It can be used as the basic raw material for powder seasoning, puffed food base powder, and nutritional meal replacement powder to enhance color and nutritional value;

2. Convenience food and ready-to-eat dishes: It can be used as a natural vegetable additive in soups, instant porridge, and stew pre-prepared materials;

3. Pet food ingredients: It is used in dry pet food such as dog food and cat food to enhance the taste and dietary fiber content;

4. Snack food and baking: It is widely used in purple sweet potato chips, biscuits, energy bars, cereal crisps and other products;

5. Meat products and sausage industry: It is used to adjust color and taste, especially suitable for plant protein meat products or vegetarian sausages;

6. Nutritional food and health products: It is mixed with other grains and beans for the development of functional powders to meet the market's needs for antioxidants and intestinal health.

Enterprise capabilities and market competitive advantages

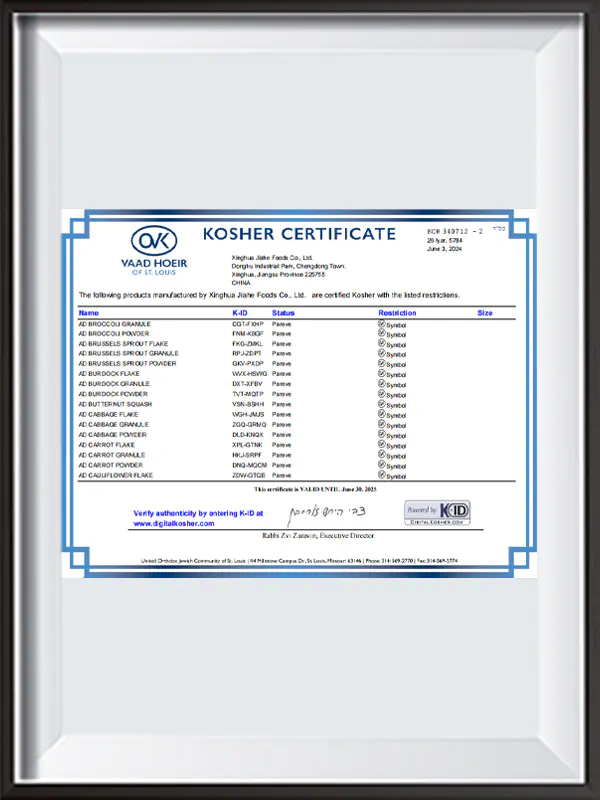

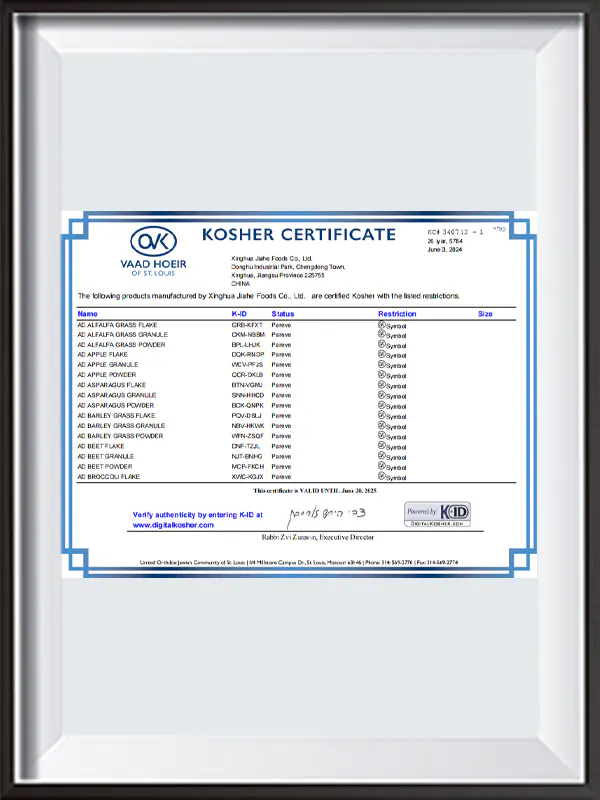

Since its establishment in 2003, Xinghua Jiahe Foods Co., Ltd. has been deeply involved in the dehydrated fruit and vegetable industry for more than 20 years and has now developed into one of the leading companies in China's dehydrated fruit and vegetable field. The company covers an area of 25,000 square meters, with an annual production capacity of 8,000 tons, and has a stable raw material supply chain and modern processing capabilities.

The significant advantages of Jiahe Food include:

Rich experience and mature technology: more than 20 years of experience in dehydrated fruit and vegetable processing, mature process standards, and stable quality;

Diversified product form supply: granular, diced, flake and powder products can be provided according to customer needs to flexibly meet the needs of different formulations;

Efficient manual quality control team: more than 300 professional hand-selected employees have built a powerful manual final inspection system to ensure that there are no foreign objects in the products leaving the factory;

Global market export experience: products are exported to Europe, America, Japan, South Korea and other markets, with a high degree of export standardization, in line with the food safety certification system of many countries.

English

English Français

Français Español

Español