Xinghua Jiahe Foods Co., Ltd is China Dehydrated Potato Manufacturers and Dehydrated Potato Factory, located in Xinghua city Jiangsu province, established in 2003. We are an experienced manufacturer and distributor of air dried vegetables and fruits in China. After more than 10 years fast development, now we are proud of being one of the top 3 manufacturers in China. We have built ourselves as a whole-range of consistent, affordable, and safe food products to the ingredient market. Our plant takes up an area of 25`000㎡with an annual capacity 8000 tons. We also have more than 300 hand-sorting workers, this is the last critical control point. Some defect materials which are out control of the facilities will be removed clearly. We have a multiple supply range. As Dehydrated Potato Exporter & Importer, we can supply you not only flake, dice, granules -- but also powder according to your need. All finish products are made from selected, fresh materials.

Dehydrated Potato

Fresh potato which are washed, trimmed, diced and dried. The processing sequence initiates with rigorous cleaning protocols, material segregation, and HACCP compliance measures before proceeding to particle size modification via blade cutting or abrasive milling techniques

- 3/8"

- 5x5xNATURAL LENGTH

- CUSTOM SIZE

Dried potatoes are widely used in food processing, including instant foods (e.g., mashed potato mixes, soup bases), snack products (chips, fries), baking ingredients, and ready-to-cook meals.

Authentic reliable quality naturally stands out and fears no comparison.

Provide you with the latest enterprise and industry news.

-

How resistant is the Dehydrated Green Pepper to microbial growth, mold, or spoilage during storage and transport?

Low Moisture Content: One of the most critical factors contributing to the microbial stability of Dehydrated Green Pepper is its extremely low moisture content achieved during the dehydration process. Water is a fundamental requirement for the growth of bacteria, yeast, and mol...

-

How should Dehydrated Tomato be stored to maintain its shelf life, color, and flavor over time?

Temperature Control Maintaining the proper storage temperature is critical for preserving the quality of Dehydrated Tomato over time. Ideally, it should be stored in a cool, dry environment between 10–25°C (50–77°F). Elevated temperatures accelerate chemical reactions such as Mai...

-

How does the particle size, cut type (shredded, sliced, diced), or granulation of Dehydrated Cabbage affect rehydration performance and application in food processing?

Particle Size and Surface Area:The particle size of Dehydrated Cabbage has a profound effect on its water absorption rate, rehydration kinetics, and suitability for different culinary applications. Smaller particles or finely shredded cabbage present a higher surface-area-to-vo...

Product definition and processing technology: the formation process of dehydrated potatoes

Dehydrated potato is dried vegetable products made from fresh high-quality potatoes, which are processed through a series of precision processes such as washing, pruning, cutting, and air drying. As a potato reprocessing product that is highly efficient and convenient to use, dehydrated potatoes not only have strict standards for raw material screening, but also introduce advanced cleaning and safety control systems in the production process.

In the specific production process, fresh potatoes with full appearance, firm texture, and no disease spots are first selected as raw materials, and the sand and impurities are thoroughly removed through a multi-stage cleaning system to ensure hygiene and safety. Subsequently, the raw materials are screened manually and mechanically, peeled, debudded, and cut into various specifications such as dices, slices, grains or strips. Then they enter the blanching or steam enzyme killing stage to prevent oxidation and browning, while retaining the natural color and flavor of potatoes.

The drying stage adopts low-temperature hot air drying or dehydration technology, and scientifically controls temperature, humidity and wind speed to maximize the nutritional value and taste structure of potatoes. In addition, to ensure product consistency and food safety, Xinghua Jiahe Foods Co., Ltd. has introduced the HACCP food safety control system and has more than 300 experienced manual sorting workers to conduct final inspections on finished products, remove non-standard discolored objects and broken particles, and form high-quality and stable end products.

Relying on the above high-standard and refined process, dehydrated potato products can be processed into different forms such as flakes, granules, dices, and powders, which are widely used in multiple food fields such as fast food, soup preparation, baked fillings and healthy snacks.

Nutritional value and product functions: convenient, highly nutritious and healthy raw materials

Potatoes have always been known as "underground apples". They are not only one of the world's major grain and vegetable crops, but also a nutritious and healthy food suitable for a diverse diet. Dehydrated potato treated with a scientific dehydration process, while retaining the original nutrition, further improve their storage, concentration and processing convenience, and are widely used in the modern food industry.

1. High potassium and low sodium, help blood pressure regulation

Dehydrated potatoes have a high potassium content and a low sodium content, and are typical "potassium-sodium balance" foods. Potassium can effectively regulate the water balance inside and outside cells, promote sodium metabolism, help lower blood pressure and prevent cardiovascular and cerebrovascular diseases. This feature makes dehydrated potatoes a recommended ingredient in the daily diet of patients with hypertension and middle-aged and elderly people.

2. Vitamin C retention, immune and anti-oxidation enhancement

Potatoes are rich in vitamin C, which has antioxidant and immune-enhancing effects. During the dehydration process, if low-temperature hot air drying technology is used, the loss of vitamin C can be greatly reduced, so that the finished product still retains active ingredients. Vitamin C can not only neutralize free radicals and slow down cell aging, but also promote iron absorption and enhance skin collagen synthesis, which is helpful for physical health and beauty.

3. Rich dietary fiber, protect gastrointestinal health

The insoluble dietary fiber and a small amount of soluble fiber in potatoes can be well preserved during the dehydration process. Dietary fiber helps promote intestinal peristalsis, increase stool volume, and excrete toxins. Long-term consumption can relieve constipation and maintain the balance of intestinal flora. At the same time, fiber also has the function of delaying the rise of blood sugar after meals and providing a sense of fullness, which is suitable for diabetic patients and weight management people.

4. Starch has strong functions and gives it diverse application characteristics

Dehydrated potato contains a high proportion of natural starch, which is extremely practical in food processing:

Strong gelatinization performance: It quickly absorbs water and expands during heating or adding water to form a smooth paste, which helps food molding;

Improved taste: It can give products a sense of viscosity and smoothness, such as sauces and soups;

Natural thickener: It is suitable for replacing some artificial colloids, such as seasonings, baking sauces, seasoning powders, etc.;

Can be used as a premixed main ingredient: It can be used as the main raw material in instant mashed potatoes, pre-made bread fillings, and meal replacement powders to provide carbon water energy and taste basis.

5. Diversified forms, flexible adaptation to processing scenarios

Dehydrated potatoes are widely used in industrial and household foods due to their high convenience and adaptability:

Granular products: suitable for instant soups, sauces, and instant porridge;

Flake and diced products: used for quick-frozen foods such as fried rice, stews, and pre-prepared staple foods;

Powdered products: made into instant mashed potatoes, puffed foods, and baking premixes, which are alternatives to healthy staple foods;

Multiple particle sizes and water activities can be customized to meet the needs of professional formulas such as baking, seasoning, and compound foods.

Industrial application and corporate strength: standardized production ensures stable quality

Dehydrated potatoes are not only one of the indispensable basic raw materials in the food industry, but also a core component of the modern convenience food system. They have extensive and in-depth applications in many fields such as fast food catering, airline catering, emergency reserves, export food, and pet food.

In convenient foods, dehydrated potatoes are widely used in products such as prepared rice, instant noodles, mashed potatoes, and instant soups, which can achieve rapid rehydration, shorten cooking time, and meet the needs of fast-paced life. In the field of healthy snacks, dehydrated potato chips can be made into low-fat potato chips by baking or light frying, which is a light food choice favored by young consumers and people who want to lose weight. In baking applications, potato flour is often used as a softener and leavening agent for bread, biscuits, and cakes due to its good water absorption and softness to enhance the taste structure.

As a powerful supplier of this product, Xinghua Jiahe Foods Co., Ltd. has focused on the deep processing of air-dried fruits and vegetables since its establishment in 2003, and has now become one of the leading companies in China's dehydrated vegetable industry. The company has strong raw material supply, processing capabilities and export qualifications. In terms of product form, the company supports product customization with multiple particle sizes, specifications, and forms, and can supply a variety of products such as flakes, granules, and powders to meet the personalized needs of different customers in terms of compounding, taste, and particle size.

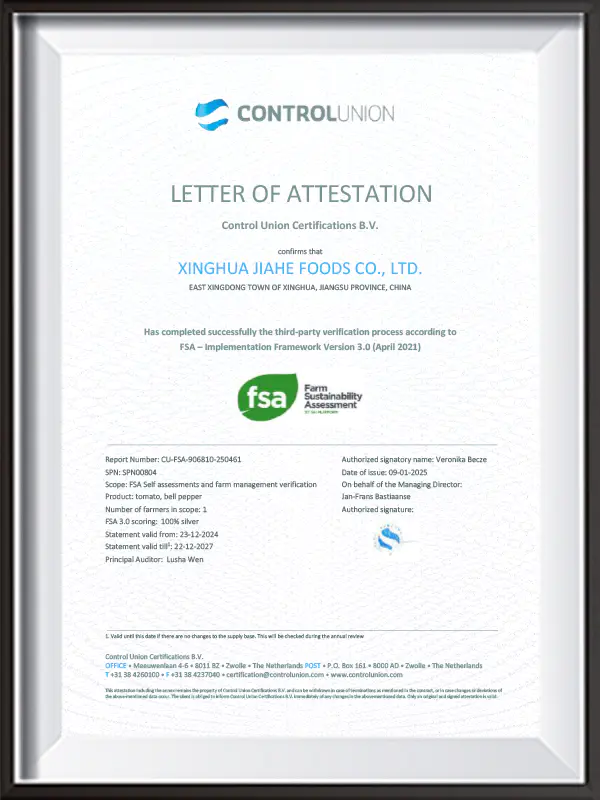

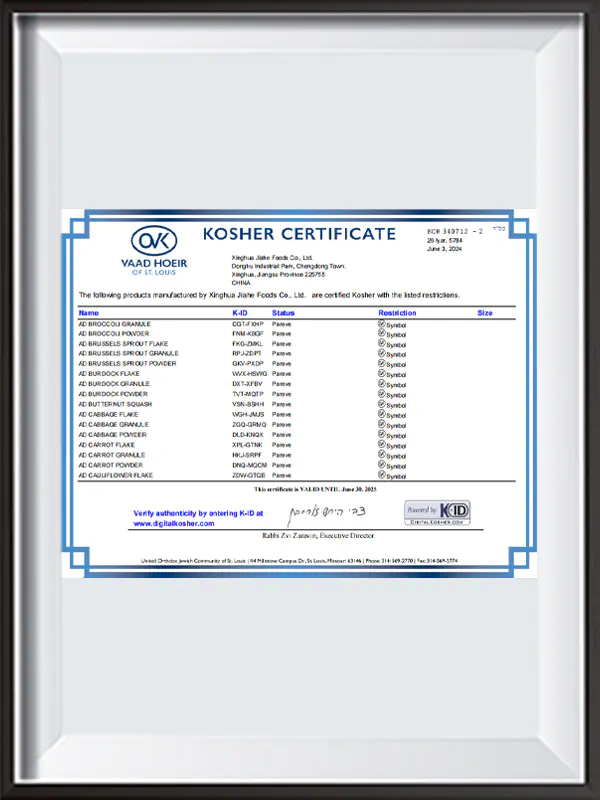

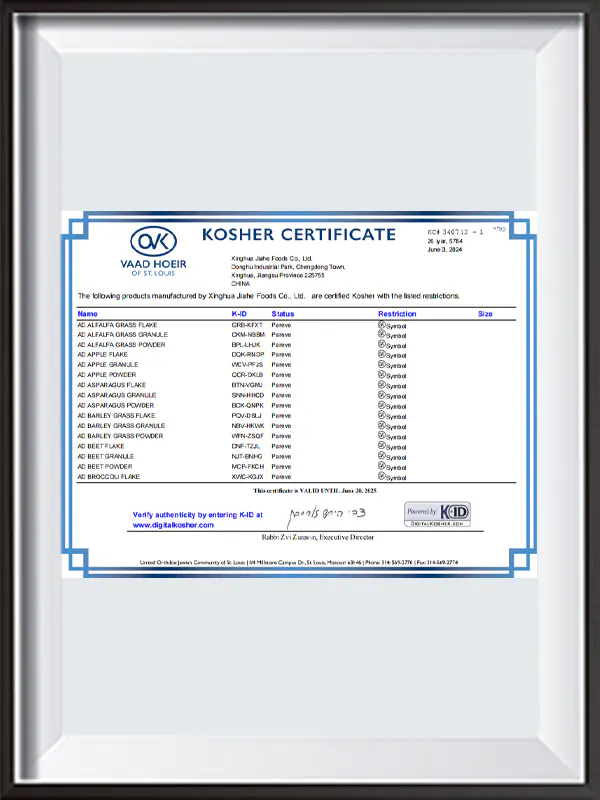

Xinghua Jiahe Foods Co., Ltd not only strictly implements international quality systems such as ISO and HACCP in terms of quality, but also introduces more than 300 manual sorting personnel in the final quality inspection link to ensure that each batch of dehydrated potatoes is clean, uniform, stable in color, and free of any impurities. Through the full-chain management of "traceable raw materials + controllable processes + factory inspection", the company has upgraded the traditional agricultural product "dehydrated potatoes" into a safe raw material with high added value in the modern food industry. The products are exported to Asia, Europe, the United States, the Middle East and other places, and have been widely recognized in the international market.

English

English Français

Français Español

Español