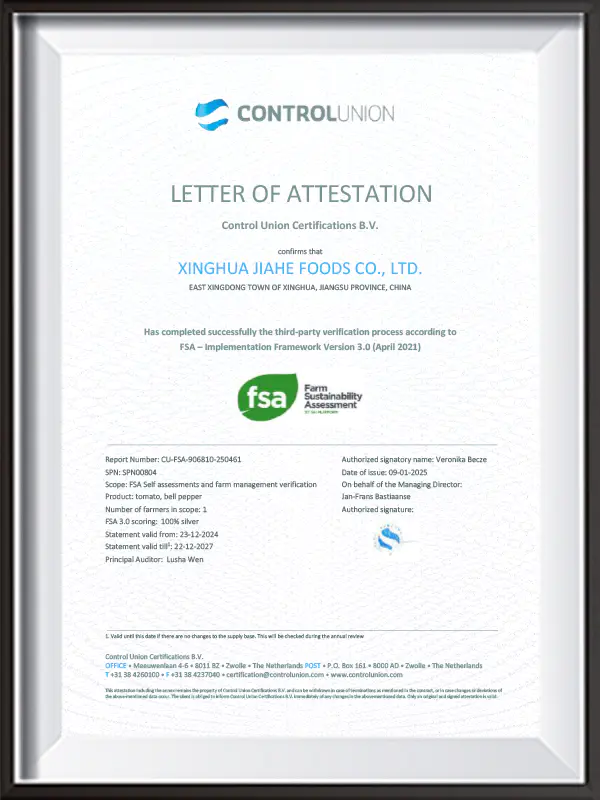

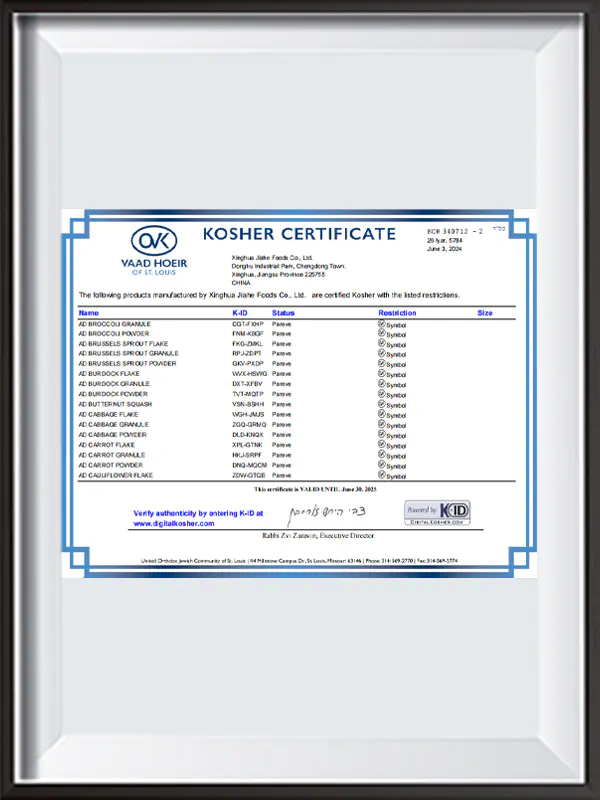

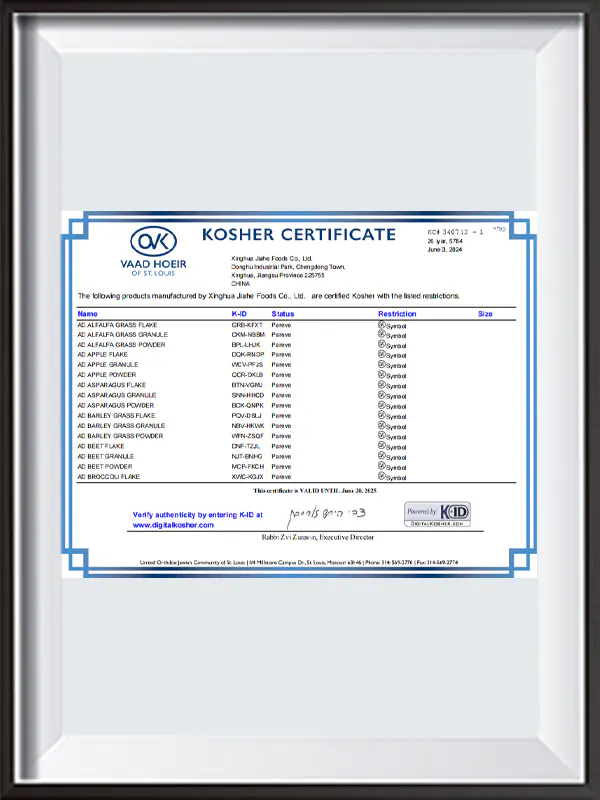

Xinghua Jiahe Foods Co., Ltd is China Dehydrated Leek Manufacturers and Dehydrated Leek Factory, located in Xinghua city Jiangsu province, established in 2003. We are an experienced manufacturer and distributor of air dried vegetables and fruits in China. After more than 10 years fast development, now we are proud of being one of the top 3 manufacturers in China. We have built ourselves as a whole-range of consistent, affordable, and safe food products to the ingredient market. Our plant takes up an area of 25`000㎡with an annual capacity 8000 tons. We also have more than 300 hand-sorting workers, this is the last critical control point. Some defect materials which are out control of the facilities will be removed clearly. We have a multiple supply range. As Dehydrated Leek Exporter & Importer, we can supply you not only flake, dice, granules -- but also powder according to your need. All finish products are made from selected, fresh materials.

Dehydrated Leek

Field fresh leeks which are washed, trimmed, cut and dried.The processing sequence initiates with rigorous cleaning protocols, material segregation, and HACCP compliance measures before proceeding to particle size modification via blade cutting or abrasive milling techniques

- FLAKES

- POWDER

- CUSTOM SIZE

Dried green and white leeks are used in seasoning blends, salad dressings and salad products, sauces, soups and stews, pasta products, cheese and dairy products, bakery products, and ready meals.

Authentic reliable quality naturally stands out and fears no comparison.

Provide you with the latest enterprise and industry news.

-

How can Dehydrated Green Pepper be blended with other dried spices or herbs without compromising flavor balance or shelf life?

Assess Compatibility of Flavor Profiles — Before initiating any blending process, it is crucial to evaluate the flavor characteristics of Dehydrated Green Pepper in relation to other spices and herbs being considered. Dehydrated Green Pepper typically possesses a mildly pungent...

-

What are the primary benefits of using dehydrated red pepper over fresh red pepper in cooking and food preparation?

Longer Shelf Life The extended shelf life of dehydrated red peppers is one of the most notable advantages over fresh peppers. Fresh peppers typically spoil within days to a week, requiring proper refrigeration and quick usage to prevent waste. Dehydrated red peppers, on the other...

-

What are the primary benefits of using dehydrated red pepper over fresh red pepper in cooking and food preparation?

Longer Shelf LifeOne of the most significant advantages of dehydrated red pepper is its much longer shelf life compared to fresh red pepper. Fresh peppers spoil within a few days to a week, depending on storage conditions, which limits their usage. Dehydrated red peppers, on th...

What is dehydrated leek and how is it produced?

Dehydrated leek is a product that is made by removing the water from fresh green onions to extend their shelf life. The process involves a series of delicate process steps designed to ensure that the final product can retain the nutrition, color, taste and aroma of green onions while being easy to store and transport. Compared with fresh green onions, dehydrated leek is much smaller in size and weight, making it an indispensable raw material in many food processing and cooking fields.

The production process of dehydrated leek starts with strict raw material cleaning. Fresh green onions are first carefully cleaned to remove soil, pesticide residues and other impurities. During this process, a HACCP-compliant cleaning solution is used to ensure that every step of the cleaning process meets food safety and hygiene requirements. The HACCP system emphasizes that every step from the source to the final product needs to be carefully controlled to ensure that food safety is not contaminated.

Next comes the pruning and cutting of green onions. According to the needs of the product, the factory will prune the green onions, remove the external unqualified parts, and cut them according to the final use. There are two ways to cut, one is knife cutting, and the other is to trim the particle size through grinding technology. No matter which method is used, the goal is to ensure that the cut green onions have uniform particle size and excellent appearance. The cut green onions will be heat treated through the blanching process. Blanching can help remove the activity of some enzymes, retain the natural flavor of green onions, and improve their color.

The key link in dehydration is drying. During the dehydration process, low-temperature drying technology such as airflow drying or freeze drying is used to ensure that the water of green onions is completely removed while retaining its nutrients and natural taste to the greatest extent. The dried green onions can be stored for a long time, are not easy to deteriorate or rot, and do not require any additional preservatives.

Why does the production of dehydrated leek require strict quality control?

The production of dehydrated leek requires strict quality control, because only through strict quality management can the safety, nutrition and flavor of the final product be guaranteed. Quality control runs through every link from raw material procurement to production process, and involves multiple monitoring measures.

Quality control starts with the selection of raw materials. To ensure the quality of green onions, Xinghua Jiahe Foods Co., Ltd conducts strict soil and water source inspections before planting green onions to ensure that there are no harmful pesticide residues and heavy metals in the planting environment. During the planting process, the company strictly manages the pesticides and fertilizers used to ensure that their use meets safety standards, and all pesticide use is recorded in detail for easy traceability and management. These measures help reduce the impact of pesticides and heavy metals on the final product.

After the green onions are harvested, the company will send the fresh green onions to an independent third-party testing agency for comprehensive pesticide residue and heavy metal testing. This link can ensure the safety of the green onions and ensure that they do not contain harmful substances that exceed safety standards. Only if the test results are qualified can they enter the production link.

In the production process, every link from washing, cutting, blanching to drying needs to be strictly controlled. In the washing process, filtered clean water is used to avoid any possible secondary pollution. When cutting and pruning, automated equipment is used to ensure the accuracy and consistency of cutting. The temperature and time during the blanching process also need to be strictly controlled to avoid excessive heating leading to nutrient loss and color changes.

Drying is a key step in the production of dehydrated leek, and it is particularly important to control the drying temperature and time. Too high a temperature may cause the aroma and nutrients of the green onion to be lost, while too low a temperature may result in incomplete removal of moisture, affecting the storage period of the product. Therefore, during the drying process, the company uses advanced low-temperature drying technology and monitors temperature and humidity in real time throughout the process to ensure the quality of the product.

After the product is completed, it is also necessary to pass laboratory testing, including physical, chemical and microbiological testing, to ensure the hygiene and nutritional content of the product. Common test items include moisture, ash content, acidity, microbial content (such as mold, coliform bacteria, etc.), and harmful substances such as pesticide residues and heavy metal content. This series of tests ensures that dehydrated leek meets various food safety and quality standards.

What is the application of dehydrated leek in the industry and what is the market prospect?

As a convenient, long-lasting and nutritious food ingredient, dehydrated leek has been widely used in many industries. It not only has a similar taste and flavor to fresh green onions, but also gradually becomes an important raw material in the catering, food processing and other industries due to its lightness and easy storage characteristics after dehydration.

In the catering industry, dehydrated leek is widely used in soups, sauces, convenience foods, frozen foods and ready meals. Since dehydrated leek can quickly absorb water and restore its original form during seasoning and cooking, it is widely used in fast food, catering takeout and instant food products. It can effectively improve the flavor and nutrition of food while reducing the storage and transportation costs of traditional green onions.

In the field of seasoning and sauce production, dehydrated leek also plays an important role. Many sauces, condiments and ready-to-eat cooking packages need to add green onions to enhance their flavor. The convenience and long-term preservation of dehydrated leek make it an ideal raw material choice.

Dehydrated leek is also widely used in the production of traditional foods and healthy foods. Many consumers prefer natural, additive-free healthy foods. Dehydrated leek has become a popular healthy ingredient because it retains the natural ingredients of green onions. Driven by the global trend of healthy eating, more and more consumers tend to choose natural foods rich in dietary fiber, vitamins and antioxidants. As a low-calorie, nutritious food, the market demand for green onions continues to grow.

From the perspective of the global market, as consumers' demand for convenient, nutritious and long-term preserved foods increases, the market potential of dehydrated leek is huge. Especially in some developed countries in Europe, America and Asia, with the accelerated pace of life, the demand for dehydrated leek is showing an upward trend. Even in developing countries, as people pay more attention to healthy eating, dehydrated leek, as a convenient food, also has broad market prospects.

English

English Français

Français Español

Español