Xinghua Jiahe Foods Co., Ltd is China Dehydrated Garlic Manufacturers and Dehydrated Garlic Factory, located in Xinghua city Jiangsu province, established in 2003. We are an experienced manufacturer and distributor of air dried vegetables and fruits in China. After more than 10 years fast development, now we are proud of being one of the top 3 manufacturers in China. We have built ourselves as a whole-range of consistent, affordable, and safe food products to the ingredient market. Our plant takes up an area of 25`000㎡with an annual capacity 8000 tons. We also have more than 300 hand-sorting workers, this is the last critical control point. Some defect materials which are out control of the facilities will be removed clearly. We have a multiple supply range. As Dehydrated Garlic Exporter & Importer, we can supply you not only flake, dice, granules -- but also powder according to your need. All finish products are made from selected, fresh materials.

Dehydrated Garlic

Fresh garlic is thoroughly washed, trimmed, cut, selected, diced, and dried. The processing sequence initiates with rigorous cleaning protocols, material segregation, and HACCP compliance measures before proceeding to particle size modification via blade cutting or abrasive milling techniques

- FLAKES

- GRANULES

- POWDER

- CUSTOM SIZE

Dried garlic is used in the production of seasonings, soups, sauces, and snacks; It can be used as a convenient seasoning at home. In addition, dehydrated garlic is also used as a health food and nutritional supplement due to its high content of allicin and antioxidant components, combining flavor and health benefits.

Authentic reliable quality naturally stands out and fears no comparison.

Provide you with the latest enterprise and industry news.

-

How resistant is the Dehydrated Green Pepper to microbial growth, mold, or spoilage during storage and transport?

Low Moisture Content: One of the most critical factors contributing to the microbial stability of Dehydrated Green Pepper is its extremely low moisture content achieved during the dehydration process. Water is a fundamental requirement for the growth of bacteria, yeast, and mol...

-

How should Dehydrated Tomato be stored to maintain its shelf life, color, and flavor over time?

Temperature Control Maintaining the proper storage temperature is critical for preserving the quality of Dehydrated Tomato over time. Ideally, it should be stored in a cool, dry environment between 10–25°C (50–77°F). Elevated temperatures accelerate chemical reactions such as Mai...

-

How does the particle size, cut type (shredded, sliced, diced), or granulation of Dehydrated Cabbage affect rehydration performance and application in food processing?

Particle Size and Surface Area:The particle size of Dehydrated Cabbage has a profound effect on its water absorption rate, rehydration kinetics, and suitability for different culinary applications. Smaller particles or finely shredded cabbage present a higher surface-area-to-vo...

What is dehydrated garlic? How is it produced?

Dehydrated garlic is a food made by removing the water from fresh garlic. It is mainly used to increase the storage life of garlic, facilitate transportation, and quickly restore the original flavor of garlic when needed. It retains all the nutrients of garlic, such as allicin and vitamins, and is suitable for various catering industries, condiment manufacturers, and retail markets.

The production process of dehydrated garlic strictly follows a series of steps of cleaning, cutting, drying, and sorting to ensure the quality of the final product. Fresh garlic undergoes a strict cleaning process to remove dirt, impurities, and external contaminants to ensure that each garlic meets the hygiene standards. The garlic will be trimmed and cut to remove unnecessary parts and maintain the quality of the garlic. After sorting, the garlic enters a meticulous cutting or grinding process, and the size of the garlic particles is adjusted by blade cutting or grinding technology to meet the needs of different customers.

Throughout the production process, the HACCP system is strictly implemented to ensure that every link is within the controllable range to avoid any food safety issues. To further ensure the quality of the product, the production line is equipped with high-precision equipment such as magnetic separators, X-ray detectors, stone removers, metal detectors, etc., to strictly monitor and screen each production link, further improving the purity and safety of garlic products. Finally, the dehydrated garlic is dehydrated through a drying process, usually using low-temperature air circulation drying to maximize the retention of garlic flavor and nutrients.

Through this process, dehydrated garlic not only extends its shelf life, but also greatly reduces the space and weight it occupies during transportation and storage. Dehydrated garlic of different particle sizes can meet different application needs, from fine powder to granules, suitable for seasonings, soups, cooking and other uses.

What are the key steps in the production process of dehydrated garlic? Why are these steps so important to the final product?

The production process of dehydrated garlic is not just about dehydrating garlic, but a complex process involving multiple links, and the quality control of each link directly affects the quality of the final product. The following are the key production steps of dehydrated garlic and their importance to product quality:

Washing and pruning: Washing and pruning are the first process in the production of dehydrated garlic, which determines the initial quality of garlic. Fresh garlic needs to be thoroughly cleaned to remove soil, impurities, pests and pesticide residues, which not only ensures the hygiene and safety of garlic, but also lays the foundation for subsequent processing. Pruning removes the outer skin and unqualified parts of garlic to ensure that every garlic is healthy, avoiding unqualified raw materials from entering the production process and affecting the quality and taste of the product.

Cutting and granulation: The cutting and granulation process adjusts the size of garlic particles through blade cutting or grinding technology. During the cutting process, the accuracy of the blade directly affects the uniformity and cutting effect of the garlic particles. Irregular particles will affect the drying process and may even lead to uneven drying, making some garlic unable to be completely dehydrated, thereby reducing product quality. In addition, the size of the granulation is also one of the competitive advantages of the product in the market. Consumers may need garlic of different particle sizes, such as powder, granules or flakes, which requires the production line to be flexible and meet diverse needs.

Drying: Drying is a key step in the production of dehydrated garlic. Through proper drying, the moisture content in garlic is reduced to an ideal level (usually below 5%), thereby extending its shelf life. Common drying methods include low-temperature air circulation drying, spray drying, and freeze drying. In this process, temperature control is crucial. Too high a temperature may cause the garlic to lose its aroma and nutrients, while too low a temperature may result in incomplete drying. The dried garlic granules can not only be stored for a long time, but also quickly restore their original flavor when heated.

Quality screening and sorting: The production line is equipped with a variety of advanced quality inspection equipment, such as AI color selection machines, metal detectors, X-ray inspection machines, etc. These devices can automatically detect foreign matter, impurities and color differences in the product to ensure that each batch of garlic meets the quality standards. Through this fine screening process, the purity and consistency of the product can be greatly improved, and the possibility of human error can be reduced. Quality control not only ensures that the appearance of the product meets the requirements, but also ensures food safety and avoids unqualified products from entering the market.

Packaging: Packaging is not only an important link to prevent product damage during transportation, but also a key step to ensure that garlic products remain fresh and high quality. Reasonable packaging can effectively prevent the influence of moisture, light and air, thereby extending the shelf life of the product. At the same time, the selection of packaging materials also needs to take into account environmental protection and economy, and try to use recyclable materials to meet international environmental standards.

How does Xinghua Jiahe Foods Co., Ltd ensure the quality and food safety of its dehydrated garlic products?

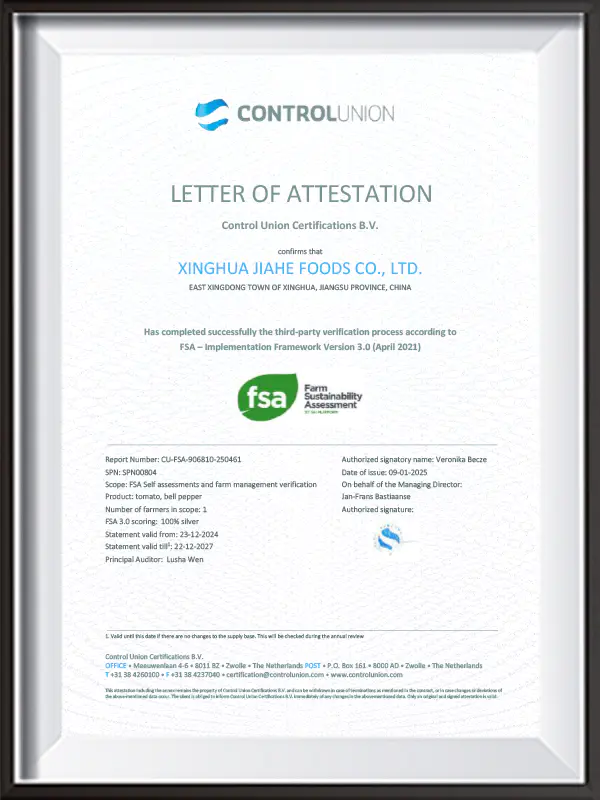

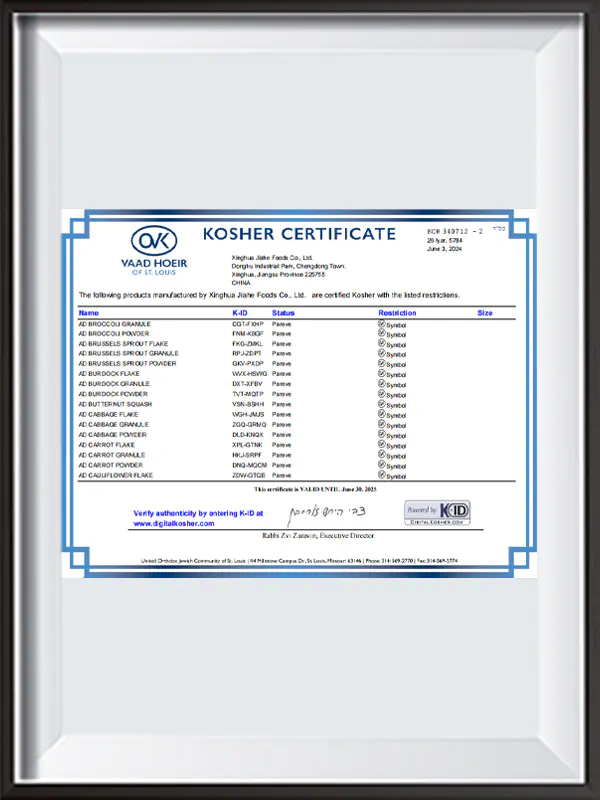

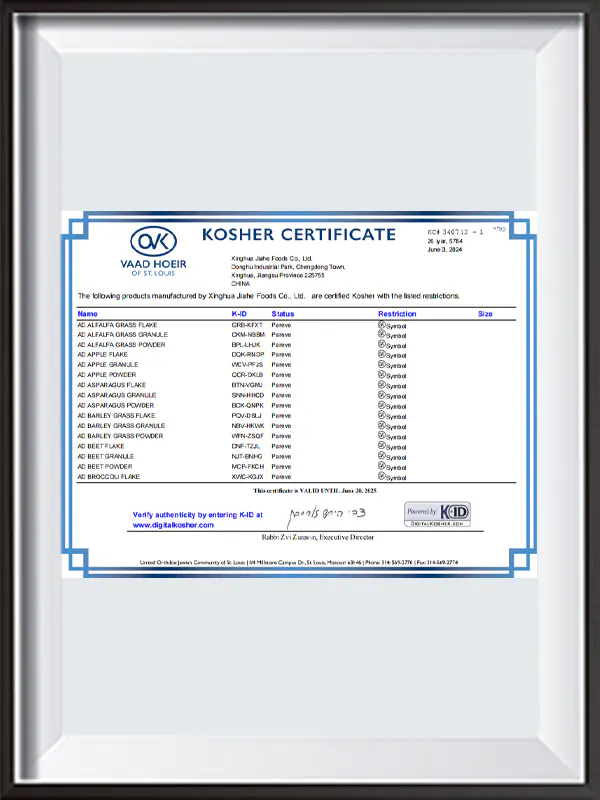

Xinghua Jiahe Foods Co., Ltd always puts quality control and food safety first in the production process of dehydrated garlic. The company has adopted full-process quality control from planting to production, and has passed a number of international certifications to ensure that its dehydrated garlic products meet the high standards of the global market.

Strict agricultural process management: From planting to harvesting, Jiahe Company always strictly controls every agricultural link, including pesticide use, weeding, fertilization, and mechanized farming. The company works with farmers to ensure that all grown raw materials meet food safety requirements and avoid pesticide residues and pollution sources. Through continuous technical training and supervision, Jiahe Company can ensure that the quality of garlic meets the company's internal high standards and ensure the high quality of dehydrated garlic from the source.

High-end production equipment and technology: Jiahe has modern production facilities and advanced equipment, such as multiple AI intelligent color sorting production lines, metal detectors, X-ray detectors, etc. The automated production process can effectively reduce human operation errors, improve production efficiency, and ensure that each batch of products can be monitored in real time during the production process. These equipment can not only efficiently sort out unqualified raw materials, but also accurately test the quality of products at each link, thus ensuring the consistency and high standards of the products.

Strict quality control system: Jiahe implements international certifications such as ISO9001:2008, ISO22000:2005, FDA, KOSHER, HALAL, Sedex and BRC A+ to ensure that every link meets global quality and food safety standards. The company's internal quality control system covers every link from raw material procurement, production and processing to the final finished product delivery, ensuring that each batch of dehydrated garlic meets strict quality standards. In addition, the company's quality management team regularly reviews and tests the production line to ensure that food safety issues are resolved in a timely manner.

Continuous product innovation and R&D: Jiahe also focuses on product innovation and R&D, and is committed to improving the taste, flavor and nutritional value of dehydrated garlic. The company regularly conducts market research to understand changes in consumer demand, continuously optimizes product production processes, and enhances product competitiveness. On the basis of quality and food safety, Jiahe continues to develop new products to meet the market demand for garlic in different forms (such as powder, granules, flakes, etc.).

English

English Français

Français Español

Español